Written by Christa Holden

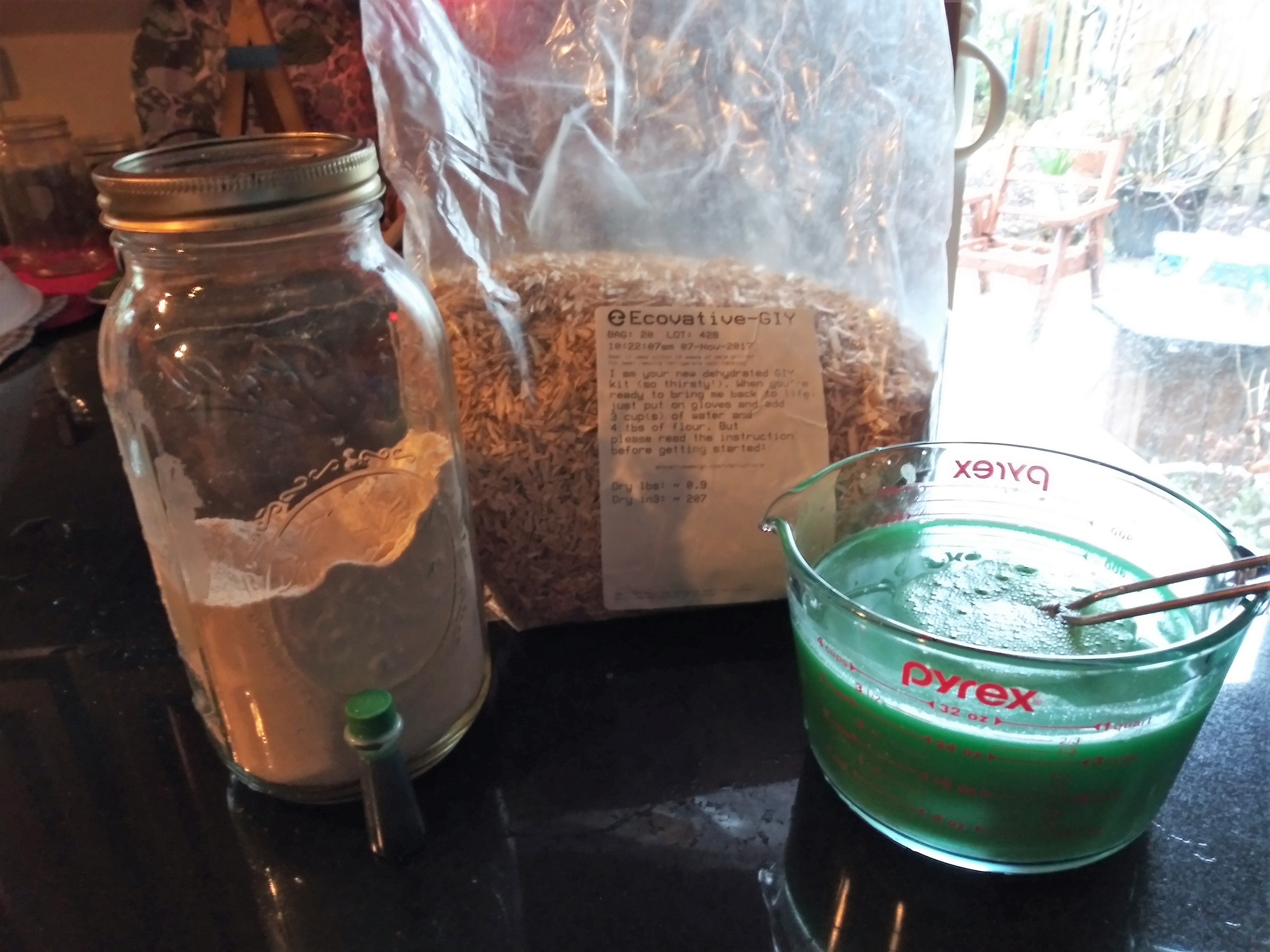

The research and use of mycelium to replace petroleum products is on! Convergence Architecture thought it would be fun to see how this stuff works so we bought a bag of inoculated substrate from Ecovative, a US company helping to research and develop mycelium products. The substrate is basically a bag of what looks like plant fiber with mycelium spores waiting to be fed and woken up to grow.

Step 1: Shake.

First, everything must be super sterile, including your hands, to avoid any contaminants getting into the bag of substrate. Simple things like dust and airborne molds can take hold and grow, ruining your batch of mycelium. The substrate comes in a plastic bag which I find a little ironic given we are trying to avoid plastic in this process, but let’s move on, as I continued the project anyways. To start, we need to moisten and feed the mycelium. This is just a mixture of flour and water. Here you will see that we also decided to experiment, and added green food coloring to our water. The color in the end will be much more muted so keep this in mind when playing with color and how much food coloring to use. Once everything is added to the bag, it is shaken until fully incorporated throughout. Now we are finished for the time being, as this needs to be set aside in a safe place and allowed to grow for 5 days.

Step 2: Form.

Again, everything must be super sterile for the handling and forming of our mycelium lampshade. Now that we have a bag of mycelium growth on our substrate we can crumble and pack it in a form. The crumbling actually stresses the mycelium and motivates it to grow more. It is like when we are working out, we stress and tear our muscles stimulating them to grow bigger and stronger. Once packed well into the form it is covered and again set aside to grow for another 5 days.

For our form we used two stacking metal salad bowls and a small tree round saved from the christmas tree end cut to space the form and become the top part of our lampshade. The mycelium will attach to organic material so I had the idea to use wood as a spacer knowing it would act not just as a spacer for the form but also become part of the shade itself. So cool. A hole was drilled between all three pieces and bolted tight to hold all together.

Step 3: Bake.

Now we are ready to release our lampshade from the form. I found that the mycelium did take hold of the wooden round and it also stuck a little to the stainless steel of the bowl. This made it a little cumbersome to get it to release and there were some minor stress cracks in the shade. This is something to think about and address the next time we use this formwork. We let the lampshade sit out in a well ventilated space for a couple of days, and used of a fan as well to aid in drying. The mycelium continues to grow some as it air dries and it was able to mend its stress cracks, although they are still visible and a good reminder of our first trial using this material. Finally, the shade is baked at a low temperature to stop the spore growth and finalize the process.

Final thoughts: The first trial was a success! I hope to give this a second trial soon… in the meantime, we’ll be wiring these up as lamps and hope to incorporate them into our new office space.